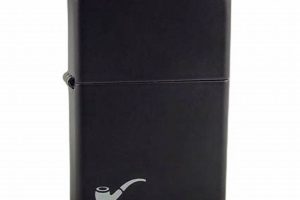

A Zippo lighter’s case comprises two primary halves. One, the outer case, is typically chrome or another decorative finish. The inner case, containing the fuel chamber and flint wheel mechanism, is frequently left unfinished, resulting in a dark gray or black appearance. This internal component is sometimes referred to by consumers using the descriptor examined here.

The contrast between the outer casing and the darker inner case is a defining visual characteristic of these lighters. This stark difference also serves a practical purpose. The less-refined finish on the internal components prioritizes function over aesthetics, focusing on durability and resistance to wear and tear from the internal mechanics and fuel. Historically, the utilitarian appearance of this internal component was not a primary design consideration, yet it has become a recognizable and accepted feature.

This discussion provides a foundation for understanding the nuances of Zippo construction, design, and functionality. Further exploration could delve into specific models, materials, or the evolution of the lighter’s design over time. Topics such as collecting, restoration, and customization can also provide further insight into the cultural impact of these iconic lighters.

Tips for Zippo Lighter Maintenance

Proper care ensures optimal functionality and longevity for any lighter. These tips focus on maintaining the internal components, crucial for reliable performance.

Tip 1: Keep it Fueled: A consistently filled fuel chamber prevents the wick from drying out, which can hinder proper ignition.

Tip 2: Replace the Flint: Regular flint replacement ensures a consistent spark. Noticeable difficulty in sparking indicates the need for a new flint.

Tip 3: Clean the Chimney: Carbon buildup can obstruct the flame. Periodically clean the chimney with a small brush or pipe cleaner.

Tip 4: Protect the Wick: Avoid bending or damaging the wick when refilling or performing maintenance. A damaged wick can result in an uneven flame or failure to ignite.

Tip 5: Address Fuel Evaporation: While unavoidable, fuel evaporation can be minimized by ensuring a tight seal when the lighter is closed. Store the lighter in a cool, dry place.

Tip 6: Inspect the Inner Case: Periodically examine the inner case for signs of wear, corrosion, or damage. Addressing these issues early can prevent more significant problems.

Following these guidelines contributes significantly to the longevity and dependable operation of a lighter. Regular maintenance not only improves performance but also preserves the lighter’s value over time.

Through understanding these maintenance practices, one gains a deeper appreciation for the craftsmanship and engineering inherent in these seemingly simple devices.

1. Inner Case

The inner case is integral to understanding the “black Zippo side.” It houses the functional components of the lighter and is the primary source of the characteristic dark appearance. Examining its facets reveals its significance within the overall design and function.

- Material Composition

Typically constructed from unplated steel, the inner case’s material contributes to its dark, sometimes almost black, appearance. This unplated steel prioritizes functionality over aesthetics. Unlike the outer case, which may feature polished chrome or other decorative finishes, the inner case’s raw finish emphasizes durability and resistance to the wear and tear associated with fuel and sparking mechanisms. This choice reflects a utilitarian approach to design, where the focus remains on the lighter’s core purpose.

- Functional Role

The inner case serves as the chassis for the lighter’s operational components: the fuel chamber, wick, flint wheel, and striking mechanism. It provides structural integrity and protection for these elements, ensuring their proper function. This internal framework is essential for the lighter’s reliability and longevity.

- Visual Contrast

The inner case’s typically dark, unfinished appearance provides a stark contrast to the often polished and decorative exterior. This visual dichotomy is a key aesthetic element of the Zippo design. The contrast highlights the separation between the lighter’s external presentation and its internal, functional core. This visual distinction reinforces the perception of the inner case as the workhorse of the lighter.

- Protective Barrier

Beyond its functional role, the inner case provides a barrier against external elements that could compromise the lighter’s performance. It shields the fuel chamber and wick from dust, debris, and moisture, contributing to the lighter’s reliability in diverse conditions. This protection ensures consistent performance and longevity.

The inner case, with its raw, utilitarian design and crucial functional role, is more than just a component; it’s fundamental to the identity of the “black Zippo side.” This unassuming element, often overlooked, plays a pivotal role in both the lighter’s operation and its recognizable aesthetic. Understanding its contribution provides a deeper appreciation for the design and functionality of the Zippo lighter as a whole.

2. Unplated Steel

The characteristic “black Zippo side” owes its appearance primarily to the use of unplated steel for the inner case. This material choice, driven by practical considerations, contributes significantly to both the lighter’s functionality and its distinct aesthetic. Examining the properties and implications of using unplated steel provides a deeper understanding of this iconic design element.

- Corrosion Resistance

While not entirely immune to corrosion, the high carbon content of the steel used in Zippo lighter inner cases provides a reasonable degree of resistance to rust and degradation, especially when compared to less robust materials. This inherent resilience is crucial given the inner case’s exposure to lighter fluid and environmental factors. The protective qualities of the steel contribute to the lighter’s longevity and reliability.

- Manufacturing Efficiency

Utilizing unplated steel streamlines the manufacturing process, eliminating the need for additional finishing steps like plating or painting. This efficiency translates to cost savings without compromising the inner case’s essential functional attributes. The pragmatic approach to materials contributes to the lighter’s affordability and accessibility.

- Functional Appearance

The unplated steel’s dark gray or black appearance results in a stark contrast with the typically polished chrome or other decorative finish of the outer case. This contrast contributes to the Zippo’s readily identifiable visual profile. The unadorned appearance of the inner case reinforces its utilitarian purpose and distinguishes it from the more decorative exterior.

- Durability and Impact Resistance

Unplated steel offers inherent durability and resistance to impacts, essential for a lighter designed for everyday carry and use. This robust material choice ensures the inner case can withstand the rigors of being carried in a pocket or dropped, protecting the internal mechanism from damage. This durability contributes significantly to the lighter’s long service life.

The choice of unplated steel for the inner case directly contributes to the “black Zippo side,” influencing both its appearance and functionality. This seemingly simple material choice reflects a design philosophy that prioritizes practicality, durability, and cost-effectiveness, resulting in a distinctive and enduring design element that has become synonymous with the Zippo brand.

3. Functional Aesthetic

The “black Zippo side” embodies the concept of functional aesthetic. The unplated, often dark gray or black, inner case isn’t merely a visual characteristic; it’s a direct result of prioritizing function over ornamentation. The raw steel, chosen for its durability, corrosion resistance, and cost-effectiveness in manufacturing, incidentally creates the distinctive “black” appearance. This unintentional aesthetic, born from practicality, became a recognizable design element. The contrast between the often polished, decorative outer case and the utilitarian inner case reinforces this duality. Similar examples of functional aesthetics include the exposed rivets on denim jeans, initially designed for reinforcement but now considered a stylistic element, and the visible bolts and gears on some watches, highlighting the intricate mechanics within.

This functional aesthetic contributes to the Zippo’s perceived ruggedness and reliability. The unplated inner case suggests a focus on performance and longevity, qualities valued by users. This resonates with the brand’s image of dependability and practicality. The “black Zippo side,” therefore, communicates a message beyond mere appearance, suggesting a history of utilitarian design choices that have shaped the product’s identity. Consider, for example, the use of raw concrete in Brutalist architecture the material’s inherent qualities create a distinct aesthetic while serving a structural purpose.

Understanding the functional aesthetic inherent in the “black Zippo side” provides insight into the brand’s design philosophy. It demonstrates how practical considerations can inadvertently create iconic design elements. This principle, applicable across various design disciplines, highlights the potential for functionality and aesthetics to intertwine and reinforce one another. The “black Zippo side” serves as a tangible example of how a focus on utility can contribute to a product’s lasting appeal and recognizable identity.

4. Contrast with Outer Case

The black Zippo side, typically the inner case, derives much of its visual identity from its stark contrast with the outer case. This juxtaposition of finishes is a defining characteristic of the Zippo lighter, contributing significantly to its recognizable aesthetic. Exploring this contrast reveals deeper insights into the design philosophy and the interplay of form and function.

- Visual Dichotomy

The contrast arises primarily from the difference in finishes. The inner case, often unplated steel, presents a dark, utilitarian appearance. The outer case, frequently highly polished chrome, brass, or another decorative finish, provides a sleek, reflective surface. This visual dichotomy creates a clear distinction between the internal, functional components and the external, presentational aspect of the lighter. This visual separation is akin to the contrast between the exposed brickwork of an industrial loft and its polished concrete floors each material signifying a different aspect of the overall design.

- Highlighting Craftsmanship

The contrast accentuates the craftsmanship involved in creating the lighter. The precise fit of the two halves, despite their differing finishes and functional roles, highlights the precision engineering required in their manufacture. The contrast allows each component to stand out, drawing attention to the meticulous construction. This is similar to how the stitching on a leather bag, contrasting with the material itself, emphasizes the handcrafted nature of the item.

- Reinforcing Brand Identity

This visual contrast has become a hallmark of the Zippo brand, contributing to its instant recognizability. The interplay between the raw, functional inner case and the polished, often personalized outer case is a key element of the Zippo’s visual language. This distinctive design element differentiates Zippo lighters from other brands, similar to how the specific grille design of a car instantly identifies its manufacturer.

- Implied Durability

The contrast subtly reinforces the perception of the lighter’s durability. The robust, utilitarian appearance of the inner case suggests resilience and functionality. This perceived strength contrasts with the more refined exterior, suggesting that the lighter can withstand the rigors of everyday use. This is comparable to how the reinforced bumpers on a truck, contrasting with the vehicle’s painted body, communicate a message of ruggedness and resilience.

The contrast between the inner and outer cases is more than just a visual element; its integral to the Zippo lighters identity. It reflects the brand’s emphasis on functionality and durability while contributing to its distinct aesthetic. The black Zippo side, therefore, is not merely a byproduct of material choice but a key component of the lighters visual and tactile language, contributing to its enduring appeal.

5. Protection from Elements

The “black Zippo side,” referring to the typically unplated steel inner case, plays a crucial role in protecting the lighter’s functional components from the elements. This protection is not the primary design intention of the unplated steel, which is chosen for its durability and cost-effectiveness. However, the material’s inherent properties contribute significantly to safeguarding the lighter’s internal mechanism. The inner case acts as a barrier against dust, debris, and moisture, preventing these external factors from interfering with the wick, flint, and fuel. Consider a toolbox made of untreated steel while its primary purpose is organization and transport, the material itself offers inherent protection against the elements for the tools inside.

This unintended consequence of the material choice has practical significance. A lighter’s reliability is paramount, especially in outdoor or challenging environments. The inner case’s protection from the elements ensures consistent performance even under adverse conditions. For example, a camper relying on a Zippo lighter to start a fire benefits from this inherent protection against wind and moisture. Similarly, a worker in a dusty environment can rely on the lighter’s consistent spark, thanks to the inner case shielding the flint and striking mechanism. The unplated steel’s resistance to corrosion also plays a role in long-term protection, preventing rust that could compromise the lighter’s functionality. This is analogous to how a galvanized steel fence, while primarily intended for boundary demarcation, benefits from increased weather resistance due to the galvanization process.

The “black Zippo side,” therefore, offers a degree of environmental protection that enhances the lighter’s reliability and longevity. While this protection is a byproduct of material choice rather than a primary design feature, its practical implications are significant. This understanding underscores the importance of considering the full range of material properties when designing functional objects. The “black Zippo side” serves as a case study in how unintended consequences of material choices can contribute significantly to a product’s overall performance and value.

6. Historical Design Choice

The “black Zippo side,” a colloquialism for the lighter’s unplated inner case, is not a deliberate aesthetic choice but rather a consequence of historical design decisions rooted in practicality and cost-effectiveness. Understanding this historical context provides valuable insight into the evolution of the Zippo lighter and how functional considerations can inadvertently shape a product’s iconic identity. This exploration delves into the key facets that connect historical design choices to the characteristic “black Zippo side.”

- Material Selection: Prioritizing Function over Form

Early Zippo lighters utilized unplated steel for the inner case due to its durability, availability, and cost-effectiveness. Plating or other finishes would have added unnecessary expense to a product designed for utility. This pragmatic approach, prioritizing function over aesthetics, established the precedent for the “black Zippo side.” Similar historical parallels can be found in the automotive industry, where early car bodies prioritized functionality and ease of manufacture over elaborate styling.

- Manufacturing Processes: Streamlining Production

The use of unplated steel streamlined the manufacturing process. Eliminating plating or painting reduced production time and cost. This efficiency contributed to the Zippo’s affordability and accessibility, factors crucial to its widespread adoption. This mirrors the historical development of many consumer products, where efficient manufacturing processes, even if resulting in a less polished appearance, contribute to market success. Consider the early production of enamelware, where the focus was on functionality and affordability rather than elaborate decoration.

- Unintentional Aesthetic: From Utility to Icon

The resulting “black” appearance of the inner case, initially an incidental byproduct of material and manufacturing choices, gradually became an accepted and even appreciated aesthetic element. The contrast between the often-polished outer case and the raw inner case created a visual dichotomy that contributed to the Zippo’s distinctive identity. This evolution from purely functional to aesthetically significant is mirrored in other design classics, such as the utilitarian aesthetic of military-inspired clothing or the industrial design of furniture made from repurposed materials.

- Brand Recognition: The Mark of Authenticity

Over time, the “black Zippo side” became associated with authenticity and durability. It served as a visual indicator of the lighter’s robust construction and its focus on functionality. This association further solidified the unintentional aesthetic as a core element of the Zippo brand. This parallels the evolution of other product features, such as the red stitching on Levi’s jeans, which transitioned from a purely functional reinforcement to a recognizable brand identifier.

The “black Zippo side,” therefore, is not merely an aesthetic detail but a testament to the brand’s history of pragmatic design choices. The interplay of material selection, manufacturing processes, and unintentional aesthetic evolution has resulted in a functional element becoming a recognizable and appreciated aspect of the Zippo lighter’s identity. This historical perspective provides a deeper understanding of how seemingly incidental choices can contribute to a product’s enduring appeal and iconic status.

Frequently Asked Questions

This section addresses common inquiries regarding the inner case of Zippo lighters, often referred to as the “black Zippo side.”

Question 1: Is the black inner case a specific design feature or simply unfinished metal?

The inner case’s appearance results from the use of unplated steel. This choice prioritizes function and cost-effectiveness over cosmetic finishes. While not a deliberate design feature initially, the contrast it creates with the outer case has become a recognizable characteristic.

Question 2: Does the unfinished steel affect the lighter’s performance?

The unplated steel contributes to the lighter’s durability and resistance to wear and tear. It does not negatively impact functionality; rather, it protects internal components.

Question 3: Why isn’t the inner case plated like the outer case?

Plating the inner case would add unnecessary cost and complexity to the manufacturing process. The unplated steel adequately fulfills its functional role without the need for additional finishes.

Question 4: Does the inner case require special cleaning or maintenance?

While the inner case itself requires minimal maintenance, keeping the lighter clean and properly fueled ensures optimal performance. Periodically wiping away any debris or fuel residue from the inner case is recommended.

Question 5: Can the inner case rust, and how can rust be prevented?

While the steel offers some corrosion resistance, prolonged exposure to moisture can lead to rust. Regular use and keeping the lighter fueled minimize the risk of rust formation. If rust occurs, careful cleaning with appropriate tools can often address the issue.

Question 6: Can the inner case be replaced if damaged?

Replacement inner cases are available, allowing for repair and extending the lifespan of the lighter. This contributes to the product’s overall sustainability and repairability.

Understanding the function and rationale behind the “black Zippo side” enhances appreciation for the lighter’s design and construction. The focus on practicality and durability has resulted in an unintentional yet iconic design element.

Further exploration could involve examining the various outer case finishes available and how they complement the inner case, creating a complete and recognizable aesthetic.

Conclusion

The unplated inner case, often referred to as the “black Zippo side,” is more than a mere component; it represents a convergence of practicality, durability, and unintentional aesthetic. Its raw, unfinished appearance contrasts sharply with the often-polished exterior, creating a visual dichotomy that has become a hallmark of the Zippo lighter. This exploration has highlighted the historical design choices, material properties, and functional considerations that have contributed to this distinctive feature. From its role in protecting the lighter’s internal mechanism to its contribution to the brand’s recognizable identity, the inner case plays a crucial role in the Zippo’s enduring appeal.

The “black Zippo side” serves as a reminder that functional design choices can have unintended aesthetic consequences. It underscores the importance of considering the interplay between form and function, and how seemingly minor details can contribute to a product’s overall character and longevity. Further investigation into the evolution of other iconic product designs may reveal similar narratives of practicality shaping aesthetics, enriching our understanding of design principles and their impact on consumer products.