Replenishing the fuel in a Zippo lighter involves introducing lighter fluid to the rayon packing material contained within the casing. This process typically entails removing the lighter insert from the outer case, lifting the felt pad at the insert’s base, and carefully saturating the packing material with the appropriate fuel. It’s essential to avoid overfilling and to ensure any spilled fluid is completely wiped away before reassembling the lighter.

Maintaining an adequate fuel level is crucial for the lighter’s functionality. A properly fueled lighter provides a reliable and consistent flame, essential for its intended purpose. Historically, Zippo lighters have gained iconic status for their dependability, a reputation built, in part, on the straightforward process of refueling. Regular fuel replenishment, therefore, contributes directly to the lighter’s longevity and performance. Beyond practical functionality, the ritual of refueling can be considered a small, tactile connection to the lighter’s enduring legacy.

This article will delve further into the specifics of this process, covering appropriate fuel types, safety precautions, and troubleshooting common issues related to fuel replenishment. Subsequent sections will address proper maintenance techniques and offer guidance on extending the lifespan of a Zippo lighter.

Tips for Fuel Replenishment

Proper fuel replenishment ensures optimal lighter function and longevity. The following tips provide guidance on achieving optimal results.

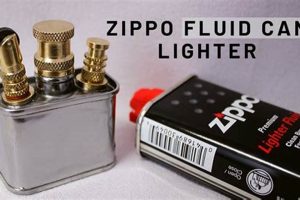

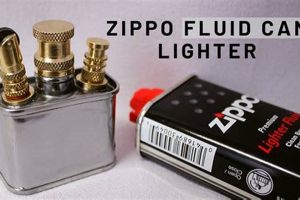

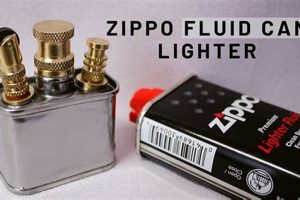

Tip 1: Use the correct fuel. Premium lighter fluid, specifically designed for Zippo lighters, is recommended for optimal performance and to avoid damaging the lighter’s components. Avoid using gasoline or other volatile fuels.

Tip 2: Work in a well-ventilated area. Lighter fluid fumes are flammable. Replenishing fuel in a well-ventilated space minimizes fire hazards.

Tip 3: Protect surfaces. Lighter fluid can damage certain surfaces. Cover the work area with a protective layer before beginning the process.

Tip 4: Avoid overfilling. Overfilling can lead to leaks and fuel spillage. Saturate the packing material until damp, not soaked.

Tip 5: Wipe away excess fluid. Any spilled or excess fluid should be thoroughly wiped away from the lighter and surrounding surfaces before ignition.

Tip 6: Allow the fluid to saturate. After replenishment, allow a few minutes for the fluid to fully saturate the packing material before igniting the lighter.

Tip 7: Store fuel safely. Store lighter fluid in a cool, dry place away from open flames and out of reach of children.

Adhering to these guidelines promotes safe and effective fuel replenishment, ensuring reliable lighter performance and extending the lifespan of the lighter.

By understanding and implementing these tips, one can maintain a Zippo lighter in optimal working condition for years to come. This attention to detail speaks to the enduring quality and craftsmanship inherent in these iconic lighters.

1. Appropriate Lighter Fluid

Appropriate lighter fluid is integral to the process of refueling a Zippo lighter. The use of specifically formulated lighter fluid ensures optimal performance and longevity. Premium lighter fluid, typically refined to a higher degree than generic alternatives, burns cleaner and produces less residue. This reduces the likelihood of clogging the wick and other internal mechanisms, thus extending the lifespan of the lighter. Conversely, using inappropriate fuels, such as gasoline or kerosene, can damage the lighter, leading to malfunctions and potentially hazardous situations. Gasoline, for example, contains additives not present in lighter fluid, which can leave gummy deposits within the lighter’s casing. These deposits impede fuel flow and can compromise the lighter’s spark mechanism. A lighter fueled with an inappropriate fluid may exhibit a weak, inconsistent flame or fail to ignite altogether.

Consider a scenario where a user fills a Zippo lighter with gasoline. The immediate consequence might be a larger, hotter flame, but the long-term effects are detrimental. Residue from the gasoline quickly accumulates, clogging the wick and hindering fuel flow. The lighter becomes unreliable, requiring frequent cleaning or even replacement of internal components. In contrast, a lighter consistently fueled with premium lighter fluid operates reliably over extended periods, demonstrating the practical significance of selecting the appropriate fuel.

In summary, the choice of lighter fluid directly impacts the performance and lifespan of a Zippo lighter. Utilizing premium, purpose-made lighter fluid safeguards the intricate mechanisms within the lighter, ensuring reliable ignition and a consistent flame. This seemingly minor detail is, in fact, a critical factor in maintaining the lighter’s functionality and preserving its longevity. Ignoring this can lead to malfunctions, costly repairs, and potentially unsafe operating conditions. Therefore, selecting and utilizing appropriate lighter fluid is not merely a recommendation but a crucial aspect of responsible lighter ownership.

2. Correct Insertion Technique

Correct insertion technique plays a crucial role in the process of replenishing fuel in a Zippo lighter. This technique involves carefully lifting the felt pad at the base of the insert and applying lighter fluid directly to the rayon packing material within. Avoid pouring fluid onto the felt pad itself, as this can lead to flooding and leakage. Precise application prevents oversaturation, which can cause fuel to seep from the lighter, creating a fire hazard and potentially damaging the lighter’s finish. A measured approach ensures the fuel is absorbed evenly by the packing material, optimizing burn time and minimizing waste.

Consider the example of two individuals refueling their Zippo lighters. One individual carelessly pours fluid into the lighter without lifting the felt pad or paying attention to the quantity. This results in overfilling, fuel leakage, and inconsistent flame performance. The other individual meticulously lifts the felt pad, applies the fluid directly to the packing material until damp, and avoids overfilling. This precise method ensures consistent fuel delivery, optimal burn time, and prevents leakage. This comparison highlights the practical importance of correct insertion technique.

Mastering the correct insertion technique contributes significantly to the longevity and reliable performance of a Zippo lighter. It prevents fuel-related issues, optimizes burn time, and minimizes the risk of leaks and spills. While seemingly a minor detail, proper insertion technique demonstrates an understanding of the lighter’s mechanics and a commitment to its proper maintenance. This ultimately contributes to the lighter’s enduring functionality and its continued status as a reliable tool.

3. Measured Fuel Quantity

Measured fuel quantity is a crucial aspect of replenishing a Zippo lighter. The amount of fluid introduced directly impacts the lighters functionality, safety, and longevity. Understanding the appropriate fill level and adhering to recommended practices ensures optimal performance and minimizes potential hazards.

- Optimal Fill Level

The optimal fill level saturates the rayon packing material without causing overflow. Overfilling leads to leakage, posing a fire hazard and potentially damaging the lighter’s finish. Conversely, underfilling results in insufficient burn time. The correct quantity provides a balance between adequate fuel supply and safe operation. Observing the fuel level within the packing material allows for precise filling, avoiding both extremes.

- Impact on Functionality

The fuel level directly affects the lighters ability to produce a consistent flame. An insufficient quantity results in a weak flame or failure to ignite. An excessive amount can cause flooding, hindering the spark mechanism and leading to fuel spillage. The proper fuel level ensures reliable ignition and a steady flame, crucial for the lighter’s intended purpose.

- Safety Considerations

Measured fuel quantity contributes significantly to safe lighter operation. Overfilling presents a fire hazard due to potential leakage. Fuel spillage onto hands or clothing increases flammability risks. Adhering to recommended fill levels minimizes these risks, promoting responsible lighter use.

- Lighter Longevity

Appropriate fuel levels contribute to the lighters longevity. Overfilling can damage internal components due to excessive pressure and fuel seepage. Consistent adherence to the optimal fill level avoids unnecessary strain on the lighters mechanisms, preserving its functionality over time.

Careful attention to measured fuel quantity is essential for safe and effective Zippo lighter operation. This practice ensures reliable ignition, consistent flame performance, and minimizes potential hazards. Furthermore, it contributes to the lighter’s overall lifespan, preserving its functionality for extended use. Understanding the relationship between fuel quantity and lighter performance allows for responsible and informed use, maximizing the benefits of this iconic tool.

4. Spill Prevention and Cleanup

Spill prevention and cleanup are integral components of the fuel replenishment process for Zippo lighters. Lighter fluid is a flammable substance, and spills present a significant fire hazard. Furthermore, the fluid can damage surfaces and leave lingering odors. Therefore, precautionary measures and effective cleanup procedures are essential for safe and responsible lighter maintenance. Preventive measures include selecting a designated workspace away from open flames and covering the area with a protective layer. Slow, controlled pouring minimizes the risk of spills, as does using the correct filling technique, which involves directing the fluid specifically into the rayon packing material within the lighter insert. These practices mitigate the potential for accidents and ensure a safe refueling process.

Should a spill occur, prompt and thorough cleanup is crucial. Immediately extinguish any open flames and ventilate the area. Absorb the spilled fluid with an absorbent material like a paper towel or cloth, avoiding spreading the spill. Clean the affected area with a mild detergent and water to remove any residue. Proper disposal of contaminated materials, in accordance with local regulations, prevents further hazards. Consider a scenario where lighter fluid spills onto a wooden table during refueling. Ignoring the spill allows the fluid to soak into the wood, creating a fire hazard and potentially damaging the table’s finish. However, immediate action, involving absorbing the spill and cleaning the area, effectively mitigates these risks. This example illustrates the practical importance of spill prevention and cleanup procedures.

In conclusion, spill prevention and cleanup are critical aspects of responsible Zippo lighter maintenance. Understanding the flammable nature of lighter fluid and employing preventive measures minimizes risks. Effective cleanup procedures further mitigate potential hazards and protect surfaces from damage. Implementing these practices ensures safe and responsible lighter use, preserving both personal safety and the longevity of the lighter itself. A comprehensive approach to fuel replenishment encompasses not only the act of filling but also the essential elements of spill prevention and cleanup, reflecting a commitment to safe and responsible lighter ownership.

5. Safe Storage Practices

Safe storage practices are inextricably linked to the process of adding fluid to a Zippo lighter. Because lighter fluid is a highly flammable substance, improper storage can lead to significant safety risks, including fire and explosion. Storing a Zippo lighter, especially after refueling, requires careful consideration of its environment. Storing a recently filled lighter in a high-temperature environment, such as a car’s glove compartment on a hot day, increases the risk of fuel expansion and leakage. This can lead to unintended ignition or create a flammable atmosphere within the confined space. Conversely, storing lighter fluid and the lighter itself in a cool, dry, and well-ventilated area, away from open flames and out of reach of children, significantly reduces these risks. This proactive approach to storage demonstrates responsible ownership and mitigates potential hazards associated with lighter fluid.

Consider a scenario where a Zippo lighter, recently refueled, is placed in a pocket alongside loose matches. Movement and friction could potentially cause the lighter to ignite, creating a dangerous situation. Alternatively, storing the lighter in a dedicated case within a secure location eliminates this risk. Another example involves storing lighter fluid near a heat source. Elevated temperatures can cause the fluid to vaporize and accumulate, creating a flammable environment susceptible to ignition. These scenarios underscore the practical significance of safe storage practices. They are not merely recommendations but essential steps in responsible lighter ownership.

Implementing safe storage practices is integral to responsible Zippo lighter ownership. It reflects an understanding of the inherent risks associated with lighter fluid and a commitment to mitigating those risks. Proper storage minimizes the potential for accidents, preserving personal safety and property. Understanding the direct connection between safe storage and the refueling process reinforces the importance of a comprehensive approach to lighter maintenance. This encompasses not only the act of adding fluid but also the crucial steps taken before and after to ensure safety and responsible use.

6. Regular Maintenance

Regular maintenance is essential for optimal Zippo lighter function and directly relates to the fuel replenishment process. While adding fluid provides the fuel source for ignition, maintenance ensures the lighter’s components operate effectively, maximizing performance and longevity. Neglecting routine maintenance can lead to malfunctions, reduced lifespan, and potential safety hazards. A well-maintained lighter, however, provides consistent, reliable performance over extended periods. Regular maintenance ensures that the lighter operates as intended, even after numerous refueling cycles.

- Flint Replacement

The flint provides the spark necessary for ignition. Over time, the flint wears down, reducing its effectiveness. A worn flint can lead to difficulty igniting the lighter or an inconsistent flame. Regular flint replacement, typically indicated by a weak spark or grinding sound, ensures reliable ignition. A fresh flint allows the lighter to function optimally even with a full fuel reservoir.

- Wick Maintenance

The wick draws fuel from the reservoir to the flame. Residue from the burning process can accumulate on the wick, hindering fuel flow and producing a weak or uneven flame. Trimming the wick periodically removes this residue, promoting optimal fuel delivery and a consistent flame. This simple maintenance task ensures efficient combustion and prevents fuel waste. A clean wick ensures the fuel added to the lighter is used effectively.

- Cleaning the Lighter Insert

Debris and residue can accumulate within the lighter insert, affecting its performance. Periodically cleaning the insert, using a soft brush and a cotton swab, removes this buildup, ensuring smooth operation. A clean insert promotes optimal fuel flow and prevents malfunctions related to clogged components. This process complements fuel replenishment by ensuring the added fuel can reach the wick efficiently.

- Inspecting the Felt Pad

The felt pad at the base of the insert prevents fuel evaporation. Over time, the pad can wear down or become damaged, leading to fuel leakage. Regular inspection of the felt pad and replacement when necessary ensures optimal fuel retention. This prevents fuel waste and minimizes the risk of leaks. Maintaining the felt pad’s integrity ensures that the added fluid is stored safely and efficiently within the lighter.

These maintenance practices, combined with proper fuel replenishment techniques, contribute significantly to the Zippo lighter’s longevity and reliable performance. Each element plays a crucial role in ensuring the lighter functions as intended, providing a consistent flame whenever needed. By understanding the interplay between these maintenance tasks and the process of adding fluid, users can maximize the lifespan and reliability of their Zippo lighters.

Frequently Asked Questions

This section addresses common inquiries regarding fuel replenishment for Zippo lighters. Understanding these aspects ensures safe and effective lighter maintenance.

Question 1: What type of fuel is recommended for Zippo lighters?

Premium lighter fluid, specifically designed for Zippo lighters, is recommended. Using other fuels can damage internal components and create safety hazards.

Question 2: How often should a Zippo lighter be refueled?

Refueling frequency depends on usage. When the flame becomes weak or inconsistent, it indicates the need for replenishment. Avoid allowing the lighter to run completely dry.

Question 3: How can fuel leakage be prevented?

Avoiding overfilling and ensuring the felt pad and closure are secure minimizes leakage. Storing the lighter upright in a cool environment also helps prevent spills.

Question 4: What should be done if lighter fluid is spilled?

Immediately extinguish any open flames and ventilate the area. Absorb the spilled fluid with an absorbent material and clean the affected area with a mild detergent and water.

Question 5: Can a Zippo lighter be overfilled?

Yes, overfilling is possible and can lead to leakage and fire hazards. Fill the lighter until the rayon packing material is damp, not saturated.

Question 6: Where should lighter fluid and Zippo lighters be stored?

Store lighter fluid and lighters in a cool, dry, and well-ventilated area away from open flames and out of reach of children.

Adhering to these guidelines promotes safe and effective lighter use. Proper fuel selection, replenishment techniques, and storage practices are crucial for maintaining lighter functionality and minimizing potential hazards.

The next section offers troubleshooting tips for common issues encountered during fuel replenishment.

Adding Fluid to a Zippo

Adding fluid to a Zippo lighter, while seemingly a simple task, comprises several crucial aspects. From selecting the appropriate fuel and employing the correct insertion technique to practicing spill prevention and adhering to safe storage practices, each step contributes significantly to the lighter’s performance, longevity, and safe operation. Regular maintenance, including flint and wick replacement, complements the refueling process, ensuring consistent ignition and a steady flame. Understanding these interconnected elements allows for responsible and informed lighter use, maximizing the benefits of this iconic tool.

The proper execution of these practices not only ensures the lighter’s functionality but also reflects a respect for its enduring design and a commitment to safe handling. By adhering to these guidelines, users contribute to the continued legacy of the Zippo lighter as a reliable and enduring tool, appreciating both its practical utility and its historical significance.